Yuyao HuaYu Electric Co., Ltd was established in 2004 and has since become a leading manufacturer of high-voltage switches and components in China. It is the leading national producer that specializes in manufacturing GIS disconnecting switches and earthing switches for voltage levels of 110kV and higher. It is recognized as a specialized and innovative enterprise in Ningbo, being designated as a Ningbo High-tech Enterprise. Additionally, it sets up the Ningbo Engineering Technology Center, demonstrating its dedication to becoming a renowned player in the domestic electric power equipment sector.

The company offers a wide range of mechanisms including three-station, common grounding, fast earthing, and common isolation mechanisms for voltage levels ranging from 10kV to 500kV. Its product range includes various mechanisms such as the HYJ4 electric mechanism, HYT5 spring mechanism, CJ8 three-station mechanism, and CJ23 three-station mechanism designed for 126-252kV GIS. Additionally, there are the HYJ4C/HYJ4D electric mechanism and HYT5D electric spring mechanism specifically developed for 500kV GIS. Furthermore, the CJ23-550 three-position mechanism is designed for 550kV three-phase linkage, making it the pioneering mechanism of its kind in China. Moreover, there is the HYT13 type circuit breaker mechanism designed for medium-voltage GIS, the CJ10/CJ10B type multi-turn output type three-station mechanism for direct-acting structure of medium-voltage GIS, and the CJ30C/CJ30G type three-station mechanism for knife-gate structure of medium-voltage GIS.

The company has successfully implemented a modern management system, and strictly adhered to the ISO9001:2015 quality management system and quality assurance system. This ensures that the product quality can be traced and maintained at a high standard. Additionally, the company has established an information management system and uses ERP and MES throughout the entire enterprise management process. This allows for a management system tailored for multi-species, small batch, and semi-customized production, ultimately ensuring on-time delivery. Furthermore, the company is equipped with a rigorous R&D system, supported by a professional team with strong capabilities and an innovative mindset. All products are developed in-house, with independent intellectual property rights, which in turn enable the company to provide comprehensive solutions to its users.

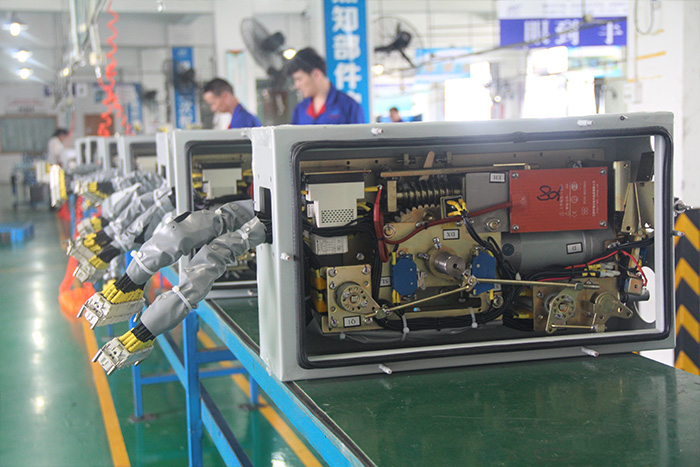

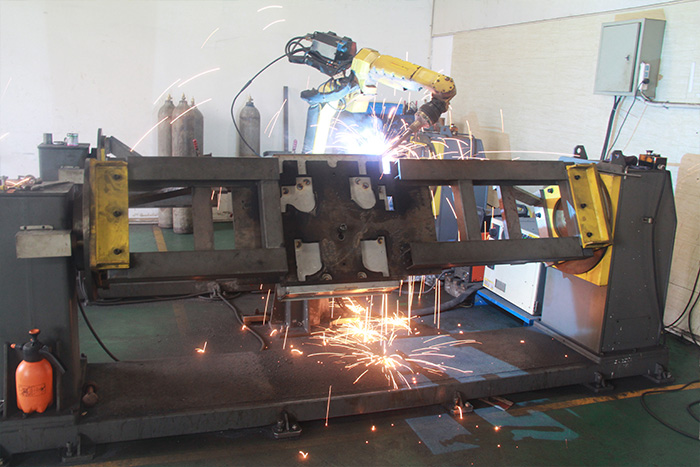

The company has equipped a wide range of advanced and sophisticated processing equipment, including machining centers, CNC lathes, welding robots, laser cutting machines, CNC grinding machines, turning and milling machines, CNC bending machines, shearing machines, wire cutting machines, gantry milling machines, surface grinding machines, various types of punching machines, and more. In total, there are over 300 sets of equipment. The assembly workshop has implemented a single-piece flow production mode, supported by the RGV line, U-shape production line, and straight-line production line. Furthermore, the company owns a full set of advanced testing equipment. The testing center is equipped with a spectrometer, physical and chemical laboratory, salt spray test chamber, shower test chamber, digital hardness testing machine, coating meter, and mechanical characteristic test equipment. There are more than 80 sets of various types of test equipment, including high and low temperature test chambers. It is with these kinds of equipment that allows us to fulfill production tasks with assured quality and quantity.

Its annual production capacity exceeds 35,000 sets. The company has established enduring and beneficial partnerships with over 50 GIS switch manufacturers, including Pinggao Electric, XI’AN XD High Voltage, Henan Pingzhi, Shandong Hitachi, Shanghai Chint, TBEA Zhongfa, Hyundai Heavy Industry, Beikai Electric, Shandong Dachi, Yunkai Electrical, Siemens Energy, TGOOD, Taikai Electric Appliance, Sieyuan, Cooper, and more. Our actuators have been utilized in over 10,000 projects by 2023, with more than 200,000 sets operating on GIS. This success has enabled us to enhance our services, improve our products, and establish ourselves as a trusted and preferred choice among manufacturers.

All staff members of HuaYu are dedicated to upholding the values of “professionalism and innovation” as they move ahead and strive for success; bearing the principles of “quality first and sincere service” in mind, they aim for excellence and never settle.

Partnering with "Huayu" means aligning with a company that is committed to growth and success. The sincere employees at HuaYu are eager to build lasting friendships with you.

The company offers a wide range of mechanisms including three-station, common grounding, fast earthing, and common isolation mechanisms for voltage levels ranging from 10kV to 500kV. Its product range includes various mechanisms such as the HYJ4 electric mechanism, HYT5 spring mechanism, CJ8 three-station mechanism, and CJ23 three-station mechanism designed for 126-252kV GIS. Additionally, there are the HYJ4C/HYJ4D electric mechanism and HYT5D electric spring mechanism specifically developed for 500kV GIS. Furthermore, the CJ23-550 three-position mechanism is designed for 550kV three-phase linkage, making it the pioneering mechanism of its kind in China. Moreover, there is the HYT13 type circuit breaker mechanism designed for medium-voltage GIS, the CJ10/CJ10B type multi-turn output type three-station mechanism for direct-acting structure of medium-voltage GIS, and the CJ30C/CJ30G type three-station mechanism for knife-gate structure of medium-voltage GIS.

The company has successfully implemented a modern management system, and strictly adhered to the ISO9001:2015 quality management system and quality assurance system. This ensures that the product quality can be traced and maintained at a high standard. Additionally, the company has established an information management system and uses ERP and MES throughout the entire enterprise management process. This allows for a management system tailored for multi-species, small batch, and semi-customized production, ultimately ensuring on-time delivery. Furthermore, the company is equipped with a rigorous R&D system, supported by a professional team with strong capabilities and an innovative mindset. All products are developed in-house, with independent intellectual property rights, which in turn enable the company to provide comprehensive solutions to its users.

The company has equipped a wide range of advanced and sophisticated processing equipment, including machining centers, CNC lathes, welding robots, laser cutting machines, CNC grinding machines, turning and milling machines, CNC bending machines, shearing machines, wire cutting machines, gantry milling machines, surface grinding machines, various types of punching machines, and more. In total, there are over 300 sets of equipment. The assembly workshop has implemented a single-piece flow production mode, supported by the RGV line, U-shape production line, and straight-line production line. Furthermore, the company owns a full set of advanced testing equipment. The testing center is equipped with a spectrometer, physical and chemical laboratory, salt spray test chamber, shower test chamber, digital hardness testing machine, coating meter, and mechanical characteristic test equipment. There are more than 80 sets of various types of test equipment, including high and low temperature test chambers. It is with these kinds of equipment that allows us to fulfill production tasks with assured quality and quantity.

Its annual production capacity exceeds 35,000 sets. The company has established enduring and beneficial partnerships with over 50 GIS switch manufacturers, including Pinggao Electric, XI’AN XD High Voltage, Henan Pingzhi, Shandong Hitachi, Shanghai Chint, TBEA Zhongfa, Hyundai Heavy Industry, Beikai Electric, Shandong Dachi, Yunkai Electrical, Siemens Energy, TGOOD, Taikai Electric Appliance, Sieyuan, Cooper, and more. Our actuators have been utilized in over 10,000 projects by 2023, with more than 200,000 sets operating on GIS. This success has enabled us to enhance our services, improve our products, and establish ourselves as a trusted and preferred choice among manufacturers.

All staff members of HuaYu are dedicated to upholding the values of “professionalism and innovation” as they move ahead and strive for success; bearing the principles of “quality first and sincere service” in mind, they aim for excellence and never settle.

Partnering with "Huayu" means aligning with a company that is committed to growth and success. The sincere employees at HuaYu are eager to build lasting friendships with you.

-

16500㎡+

Plant Area

-

99650+

Engineering Applications

-

42+

Product Aategories

-

195K+

Put Into Operation

Production equipment

The original intention remains the same, advancing with the times. The development of "Huayu" is your ideal partner! Sincere Huayu people are willing to become your loyal friends!